Shenzhen Juke Industry Co., Ltd.

Tel: (86) 755-25566186

Fax: (86) 755-29668058

E-mail:jakizhu@163.com

Contact:

Zhu Wenwu

Mobile: 13928444330

QQ: 504060299

Zhu Ganghui

Mobile: 13714798680

QQ: 1046243838

Miss Zhou

Mobile: 13066916396

QQ: 1253838927

Address:1006 Huamei Building, Huamei Road, Songgang, Bao'an District. Shenzhen

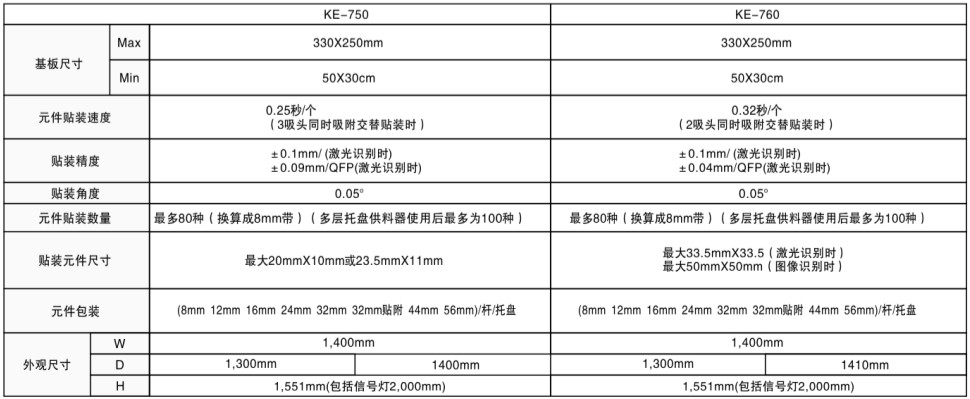

Product Name:juki760 Mounter

Place of Origin: JAPAN (Japan)

Performance:

Perfect patch speed: 0.32sec/

chip-Chip precision: Within+/-0.15mm-

SMD component range: 1005~50mm QFPs.-

Equipped rack: 80 stations.

PCB Dimensions: 330mm*250mm

PCB thickness: 0.40 mm (min) -4mm (max)

technical parameters: (F5, pick & place head ):

component placement range: 0402-48mm * 48mm (Chip, SOT, SOP, MELF, a QFP,

Connector, SOP, PLCC)

element height :0.3mm-10.5mm.

Pin Spacing (Min ): 0.4mm.

Component Dimensions: 0.5mm*1.0mm (Min), 23.5mm*23.5mm (Max).

Nozzle Type: 10X, 20X.

Mounting Accuracy : +/- 0.1mm (LA), +/- 0.04mm (LAIC)

Mounting speed (Max): 11,250 components/hour.

Juki760 Mounter Specifications

juki760 Mounter Routine Maintenance

Check the part name every week. Procedure Remarks The nozzle clamp checks the buffer action. If the action is not smooth, apply a thin layer of lubricant. If the clamp is loose, tighten it. Move the lens to clean dust and residue from the lens. X-axis lead screw Check screw for debris or residue and clean if necessary. X-axis guides check for grease hardening and residue adhesion. Y-axis lead screw Inspect the lead screw for debris or residues and clean it if necessary. Y-axis guides check for grease hardening and residue adhesion. W-axis lead screw Check the lead screw for debris or residue. If necessary, clean the air interface. Check the Y-ring and O-ring for deterioration. Replace if necessary.