Shenzhen Juke Industry Co., Ltd.

Tel: (86) 755-25566186

Fax: (86) 755-29668058

E-mail:jakizhu@163.com

Contact:

Zhu Wenwu

Mobile: 13928444330

QQ: 504060299

Zhu Ganghui

Mobile: 13714798680

QQ: 1046243838

Miss Zhou

Mobile: 13066916396

QQ: 1253838927

Address:1006 Huamei Building, Huamei Road, Songgang, Bao'an District. Shenzhen

Product Name:juki2060 Mounter

Place of Origin: JAPAN (Japan)

Product Information:

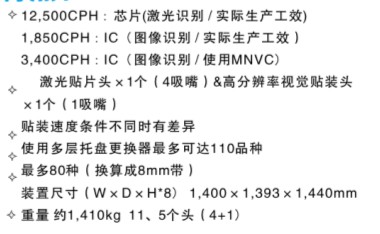

1,12,500CPH: chip (laser identification / actual production ergonomics)

1,850CPH: IC (image recognition / actual production ergonomics)

3,400CPH: IC (image recognition / use MNVC)

2, laser patch head × 1 (4 Nozzles) & High-Resolution Visual Mount Heads × 1 (1 Nozzle)

3, Laser Recognition: 0603 Chip (Inch 0201) Chip ~ 33.5mm Square Element

0402 (Inch 01005) Chips are shipped from the factory Option

4, Image Recognition : 1.0×0.5mm*2 to 74mm square element or 50×150mm

(0402 (inch 01005) chip requires options)*7 Image recognition

(reflection/transmission recognition, ball recognition, segmentation recognition)

5. Mounting speed conditions Different from time to time

6. Use up to 110 varieties of multi-layer tray changers.

7, substrate size M substrate (330 × 250mm) for L substrate (410 × 360mm)

Lwide (510 × 360mm) E substrate (510 × 460mm) * 1

8, up to 80 (converted into 8mm band)

9, the device Size (W×D×H*8) 1,400×1,393×1,440mm

10 Weight 1,410kg 11,5 heads (4+1)

Features of

juki2060 Mounter juki2060 Mounter specifications

Introduction of juki 2060 placement machine The

automatic placement machine is a device for realizing high-speed, high-precision and automatic placement of components, and is the most critical and most complex device in the entire SMT production. The SMT machine is the main equipment in the SMT production line. The SMT machine has evolved from an early low-speed mechanical placement machine to a high-speed optical centering machine, and has developed modularly into a versatile and flexible connection.

Juki2060 SMT machine control part

1, drive cylinder, solenoid valve and piping, connector no foreign matter blockage, no loose leakage. Drive cylinder and solenoid valve work normally, no noise;

2, compressed air drying filter device is complete and intact.