Shenzhen Juke Industry Co., Ltd.

Tel: (86) 755-25566186

Fax: (86) 755-29668058

E-mail:jakizhu@163.com

Contact:

Zhu Wenwu

Mobile: 13928444330

QQ: 504060299

Zhu Ganghui

Mobile: 13714798680

QQ: 1046243838

Miss Zhou

Mobile: 13066916396

QQ: 1253838927

Address:1006 Huamei Building, Huamei Road, Songgang, Bao'an District. Shenzhen

Product Name:juki2050 Mounter

Origin: JAPAN (Japan)

Specifications:

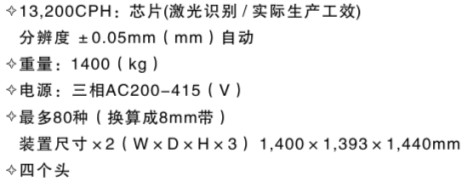

1,13,200CPH: chip (laser recognition / actual production ergonomics)

resolution ± 0.05mm (mm) automatic

2, laser patch head × 1 (4 nozzle 0603 (Inch 0201)

chip ~ 20mm square element or 26.5×11mm

0402 (Inch 01005) The chip is shipped with optional mounting

speed conditions vary from time to time.

4. Board size: E board (510×460mm)

Lwide (510×360mm) L board (410× 360mm) For

M substrate (330×250mm)

5、Weight: 1400(kg)

6、Power supply: Three-phase AC200-415(V)

6, Up to 80 kinds (converted to 8mm tape)

Device size×2(W×D× H×3) 1,400×1,393×1,440mm

7.

Features of the four-head juki2050 placement machine

juki2050 Mounter specifications

juki2050 Mounting accuracy of the placement machine is

the maximum offset between the center of the element and the corresponding pad centerline, not Exceeds 1/3 of the width of the component's welding feet (visual inspection), or the occurrence of abnormal deviation is not more than 3. The

appearance of the instrument and instrument is good, the indication is accurate, the reading is conspicuous, within the qualified use period, the

equipment is regularly maintained inside and outside, kept clean, Non-oily, no rust, with accessories arranged around, etc., equipment lubrication Good.

Routine maintenance juki2050 placement machine

Check the part name every week. Procedure Remarks The nozzle clamp checks the buffer action. If the action is not smooth, apply a thin layer of lubricant. If the clamp is loose, tighten it. Move the lens to clean dust and residue from the lens. X-axis lead screw Check screw for debris or residue and clean if necessary. X-axis guides check for grease hardening and residue adhesion. Y-axis lead screw Inspect the lead screw for debris or residues and clean it if necessary. Y-axis guides check for grease hardening and residue adhesion. W-axis lead screw Check the lead screw for debris or residue. If necessary, clean the air interface. Check the Y-ring and O-ring for deterioration. Replace if necessary.